Case Study FIW - Focused Improvement Workshop

Sep 06, 2020

The Challenge

The Lab in this large, multi-hospital system implemented a Lean Processing Cell in their core lab, improving their turn-around-time by over 50%. However, the samples requiring manual evaluation were still being handled in the old environment. This created inconsistent turn-around-times and had a negative impact on staff morale. The department manager decided that the Manual Cell was ready for a Lean workshop. The challenge was established: overhaul the Lab Manual Cell in a 3 day focused event. This undertaking included everything from when the order was received in the Manual Cell inbox to when the results were completed and the sample either stored or discarded.

Before - Extra space was used for storing unneeded items and the underutilized refrigerator was occupying key floorspace

Targets

An eight-member team was established to address four primary targets. They included:

- Reconfigure the Manual Cell to reduce traffic flow and enhance productivity

- Establish a maintenance and quality control schedule

- Standardize the workstation supplies

- Develop visual controls for maintenance, quality control and work balance

Areas of Focus

While this Focused Improvement Workshop primarily focused on the Lab Manual Cell, there were three sub- processes that also fell into the project scope. They included: maintenance/quality control schedule, dilution station in the auto cell, and point of care work area. Representatives from each area and sub-process were involved in the Team.

Workshop Actions

The Team, along with resource representatives from Facilities, Maintenance and LIS, completed almost all of the necessary actions during the actual workshop week. This Lean approach was a huge success. Below are some of the actions taken to help drive their victory.

- Moved refrigerator and replaced it with one that was “right-sized”

- Relocated previously underutilized cabinets

- Increased work station space

- Developed visual controls for reference materials and binders, placed them in central location and labeled them

- Labeled workstation supplies

- Cleared walkways

- Created visual boards for Work in Progress and

- Maintenance/Quality Control

- Created space for Lab jackets by the break room

- Created one dilution station with all equipment necessary at point of use

- Developed and implemented a sustaining plan

- Developed and implemented an audit monitoring system

- Developed an audit tool for maintenance and quality control

After: Relocated previously underutilized cabinets

which added 20’ of needed work space and replaced the refrigerator with one that was “rightsized”, creating space for 3 test zones.

Outcomes

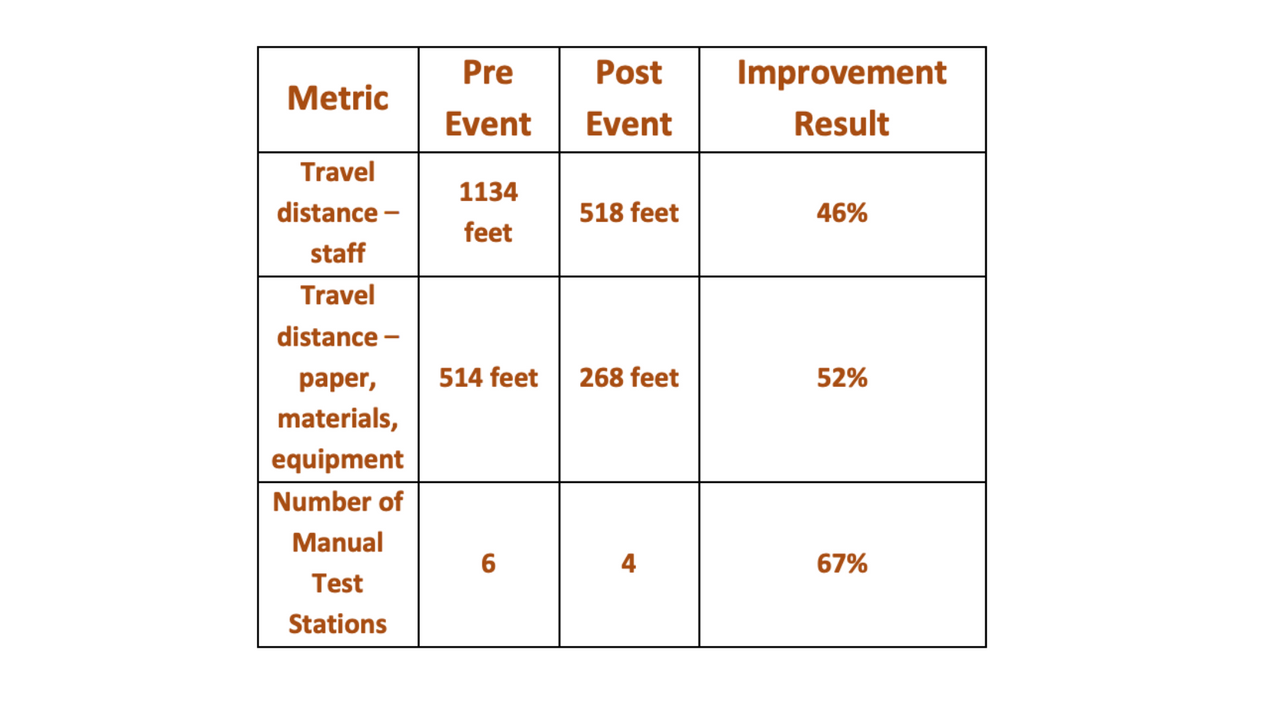

A value-added analysis was completed at the end of the workshop and showed 52% overall improvement in the space and processes within the Lab Manual Cell. These accomplishments were incredible but the outcomes didn’t stop when the workshop ended. Positive results continue to acquire. For example, staff satisfaction continues to increase, processes are getting more efficient, search time continues to decrease and workloads are more leveled

Client Testimonials

The Team did an outstanding job of exceeding their vision of “designing the manual cell so that it has improved traffic flow and provides all equipment, supplies and training needed to perform work in a supportive environment.”

Results

Stay connected with news and updates!

Join our mailing list to receive the latest news and updates from our team.

Don't worry, your information will not be shared.

We hate SPAM. We will never sell your information, for any reason.